Train Addiction Help Line: 1.866.840.7777

Feb 4, 2019 - HO Scale

Differences Between Hawker Siddeley and Marine Industries 4 Bay Cylindrical Hoppers

Summary of Differences between the 4550 cu ft Hawker-Siddeley and the Marine Industries Cylindrical Hopper:

The Marine Industries Limited (MIL) 4550 cubic-foot cylindrical covered hopper appears at first glance to be identical to the Hawker Siddeley (HST) 4550, so why’d we tool this car? Well, the bodies and side sills are identical, when you compare the the number and size of side panels and the design of the side sill. But, other than the body and side sill being the same, most of the rest of the car has detail differences.

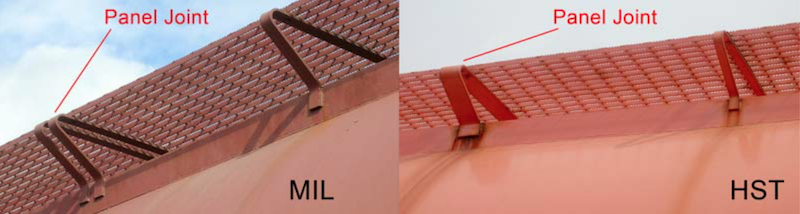

Starting with the roof, the MIL 4550 has a total of 14 running board supports, all the same width with a pair of supports at each running board panel joint. This differs from the HST design which utilizes narrow and double width supports, with the double width supports at the running board panel joints.

Comparison of MIL and HST running board supports

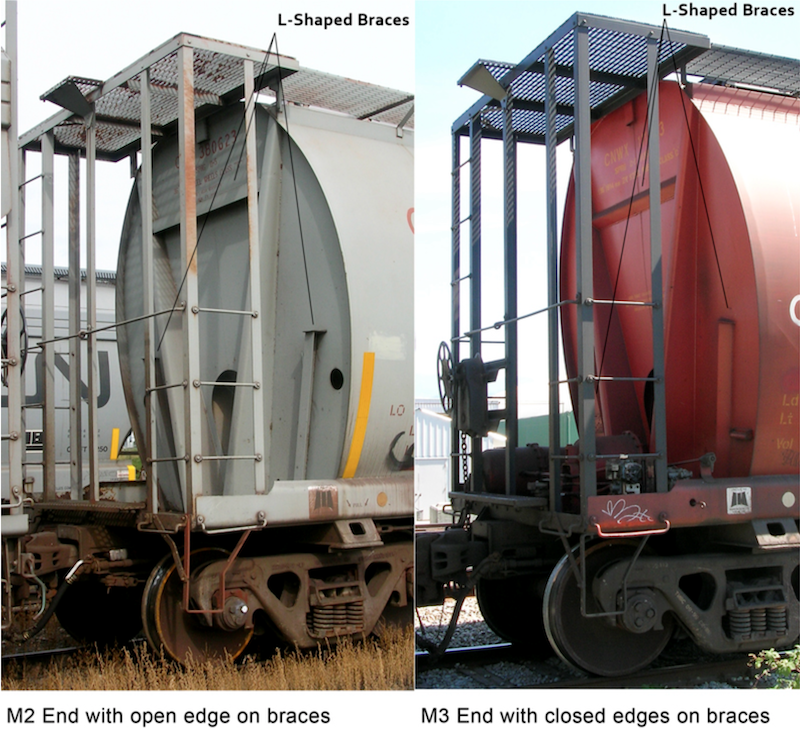

The ends also are different on the MIL car, compared to the HST versions we have produced. We tooled both MIL end styles. The first end (M2) has L-shaped short vertical braces, with one leg welded to the end sheet and the outboard edge open.

The second end we tooled (M3) has slightly different short vertical braces. While still fabricated from angle-stock, this time both legs are welded to the end sheet, creating an inverted V-shaped brace.

Three different ends were tooled for the HST 4550, all slightly different from the two new MIL ends.

The B-end brake gear layout (air reservoir, control valve, piping, etc.) differ slightly on the MIL version of the car compared to the HST versions, and we took this detail into account and tooled new brake gear for the car.

MIL B-end brake equipment layout

The MIL version of the end frame is slightly different from the HST version. The HST end frame upper platform frame on the left end of the car (both sides) is recessed behind the vertical ladder stiles, while on the other end of the car, the frame is on the outside of the ladder stiles. This results in the running board end platform sticking out on one side of the car further than the other. The MIL version is not recessed on the left end of the car, but is the same on both sides, with the frame on the outside of the ladder stiles.

Side frame outside of ladder stiles (MIL) Side frame recessed behind ladder stiles (HST)

While this is a minor detail difference, we chose to tool the new end frames for the MIL car so that it is as accurate as possible.

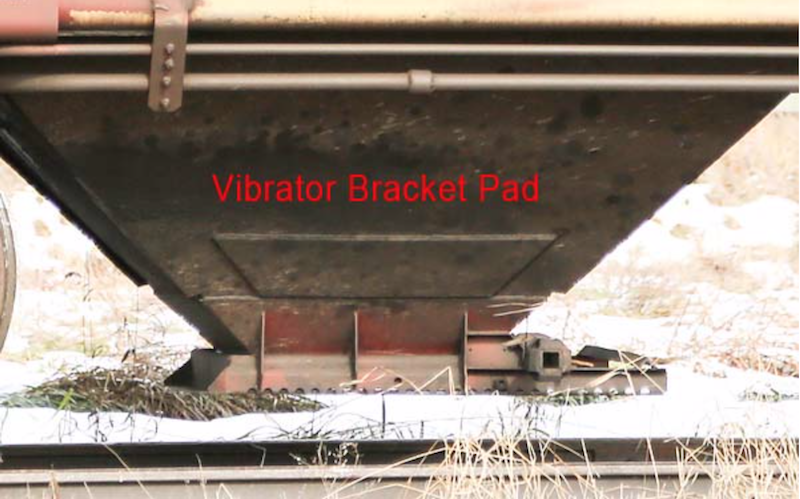

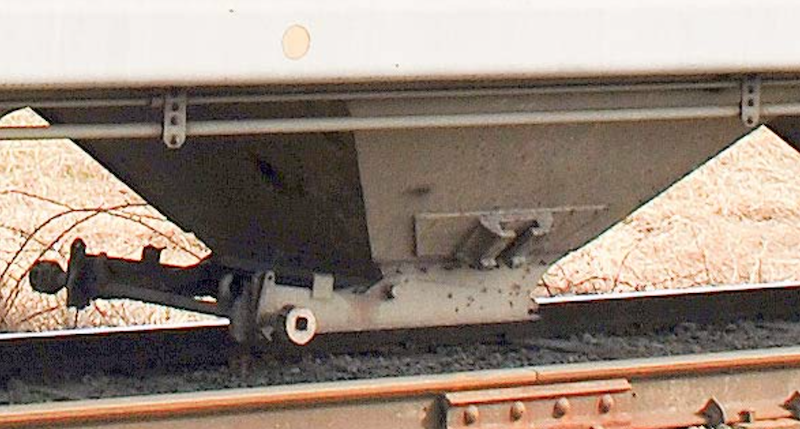

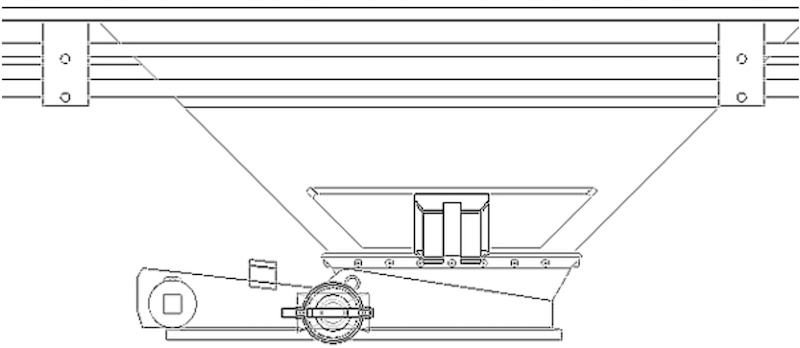

Both the HST and MIL versions of the 4550 were delivered with vibrator bracket mounting pads on the right-hand sides of the hoppers (with the B-end to the left). None of the HST cars were delivered with vibrator brackets, just blank mounting pads. However, some of the MIL cars were delivered to CN with vibrator brackets, so we tooled up some vibrator brackets so that the specific cars that have them can be accurately modeled.

The vibrator bracket pads were standard on both the MIL and HST versions of the 4550 (on right side of the car only)

One order of cars for CN, 382000-382699, were the only 4550s delivered by either MIL or HST with vibrator brackets. CN pulled 25 cars from this series and modified them with gravity/pnumatic outlet gates, and left the vibrator brackets in place.

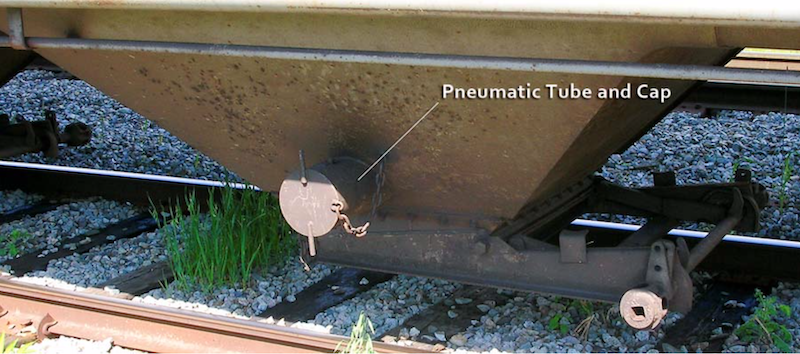

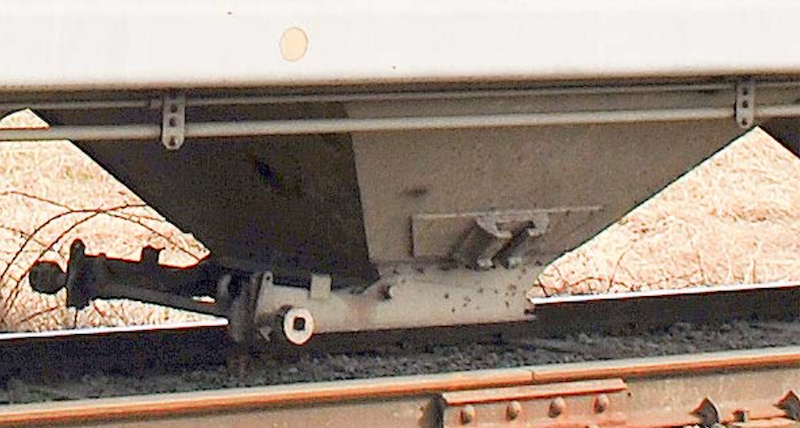

Along with added vibrator brackets, some of the cars delivered to CN were modified for both gravity and pneumatic unloading. Two series of cars, CN 380600-380604 and CN 380619-380628, for a total of 15 cars, were modified by replacing their original gravity Toggle Lock outlet gates with gravity/pneumatic

Toggle Lock outlet gates. The pneumatic tube is mounted down on the side frame of the outlet gate. We have accurately tooled this outlet gate so these two series of cars can be accurately modeled.

Another series of cars, CN 380800-380809 were modified by attaching pneumatic outlet tubes directly to the hopper bays above the Toggle Lock gravity outlet gates.

Since we are discussing outlet gates, it should be mentioned that CN ordered their cars with bolt-on outlet gates while CP ordered theirs with welded-on outlet gates. Like on the HST models, both riveted and welded outlet gates are accurately modeled on the MIL replica cars.

CP welded outlet gate

Starting in 2003 when CN and CP took ownership of the CNWX and CPWX fleets of covered hoppers, both roads ran their “new” cars through modification programs in order to extend the life of these cars. Modifications included new control valves, new truck-mounted brakes, new outlet gates as required and reinforcing gussets welded to the side sill where the outboard corners of the two outboard hopper bays neet up with the side sill. Because of the shape of the side sill (roughly a C-shape) and how stresses are transmitted, cracks have started forming at the four corners of the car which need to be drilled to stop the migration of the cracks, plus a gusset is welded over the area that is cracked. Because the side sill on both the HST and MIL versions are identical, they both require this fix.

Included on applicable models are formed metal gussets and replacement outlet gates. CN tended to go with Holden International outlet gates while CP went with Miner Enterprises outlet gates. We have accurately tooled both of these outlet gates so that they can be added to applicable versions of the MIL car.

Holden International welded replacement outlet gate (CN)

Miner Enterprises welded replacement outlet gate (CP)

We also modified the draft gear (coupler pockets) so that it is closer to scale width and the MIL 4550s will be delivered to your layout with authentic Kadee No. 58 semi-scale whisker couplers.

All-in-all, we have tooled 18 versions of the MIL 4550 (2 ends, 7 outlet gates, pneumatic tubes, tack boards and reinforcing gussets) to cover virtually every MIL 4550 delivered between February 1980 and March 1987 and the later modified cars. We think that you will appreciate the subtle differences between the HST and MIL versions of the ubiquitous 4550 cubic foot cylindrical covered hopper!

We have also made small and large tack boards for the appropriate cars.