|

Dear N Scale Customers:

Last year we produced a 48 car CP Rail Coal Car Train. This year

we will produce a 48 car Sulfer Train using

the Intermountian Bathtub Rotary Dump Bathtub Coal Cars.

Many of you may be asking why Pacific Western Rail did 48 road

numbers? Well that's easy to explain - have you ever seen a coal

train go by with repeating road numbers every 12th car? We

haven't, so we thought we would make enough road numbers to satisfy

most of our customers needs.

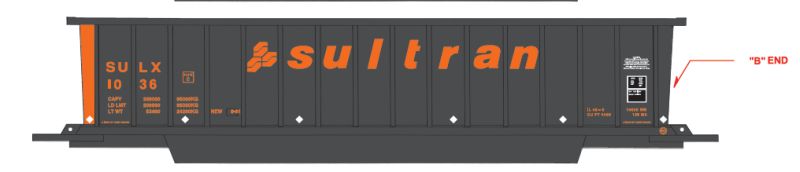

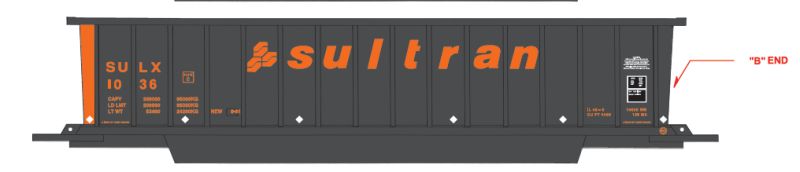

So we are now announcing our next 48 car unit train set to be

done in Sultran (with Horizontal Lettering). Back in 2005, we

lobbied Intermountian to produce the Bathtub Coal Car. We were

given our choice of an exclusive run on either of the two paint

schemes that can be run in Sultran.

Since the Horizontal Scheme is the more previlant of the two, we

chose to do a run of the Horizontal Scheme instead of the

rare Vertical Scheme.

Intermountain has released 24 of the cars with the Vertical

Sultran Scheme. So we will now release a 48 car set of the Sultran

Bathtub cars with the Horizonal Graphics.

We had planned all along to hold back on releasing these until

Intermountain had released the 24 Vertical Schemed Cars so you

would not have to buy all 72 cars at once.

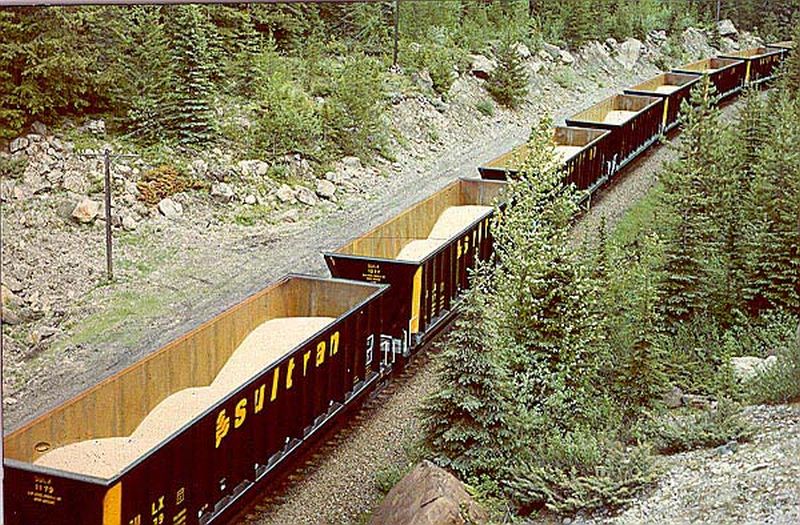

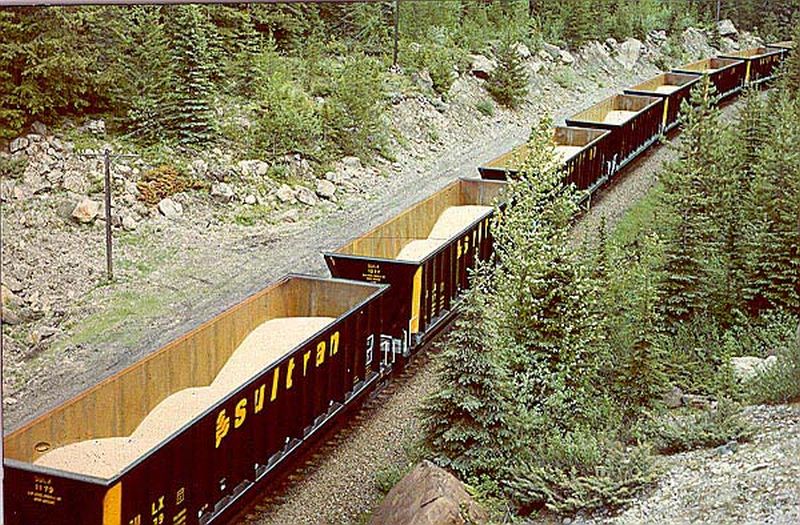

We typically see these trains coming through

Vancouver in about a ratio of Horizonal to Vertical Cars of

about 4-2. So if you get the 48 car special run from Pacific

Western and get 12-24 of the Vertical Sultran cars that

Intermountian released, well you have a great 72 car black snake

with yellow sulfer loads. Add a couple of Red CP Rail Kato AC4400's

or a Blue Kato CEFX Lease AC4400 units to the fromt of the train

and you have an awesome site to look at and run.

So here they are, enjoy! We have included some corporate

information on Sultran and there opperations in Western Canada.

These cars should be of interest to all of our customers who run

BC Rail, CN, & CP Rail.

We will release these cars in about 3 months. Intermountain has

already sent plastic to China for the run. So the run size is

locked down. If you do Western Canadian Model Railroading in 1975

to present don't miss out.

Sultran Twenty Year History In the early 70's sulphur was a very

abundant yet low-value commodity and there were few markets for the

product in Canada. Logistics for handling and transporting the

element were chaotic, costly and unreliable. Sulphur producers were

frustrated by the inability to dependably and efficiently access

growing world markets. As sulphur slowly showed signs of escalating

in demand and value, it became apparent that improved methods of

transporting and handling the commodity would need to be developed.

These new methods had to be cost efficient, environmentally sound

and offer reliability and dependability to the sulphur industry and

its customers.

By the mid-seventies the beginnings of a company that would assist

the industry were underway. Over the next twenty years Sultran

would have an important impact on the outcomes and achievements

this industry would yield. The result is a successful company that

through careful, thorough, and competent measures, transports this

commodity from the processing plants to tidewater in a manner that

allows its full marketable potential to be realized.

In September of 1974, Petrofina, Shell Canada Resources and Hudson

Bay Oil & Gas became key members of an eight-member industry

task force. They were assigned the responsibility of developing a

mandate for a producer-owned, independently managed, sulphur

logistics service company, incorporating the business and offering

shares to all interested producers.

On December 16, 1975, after a great deal of work by industry

members, Sultran was incorporated as a private company with

twenty-three shareholders holding 905,000 shares. In August of the

following year, staffing commenced in Calgary with the appointment

of the Company's first president and the opening of a tidewater

office in North Vancouver. By December 1976, the Company was

solidly in place and an eight-member team began the operation of

Sultran Ltd. By January 31, 1977, twenty-one customers had signed

long term service contracts, called User Agreements, with Sultran.

These Agreements solidified the industry's commitment to Sultran

and conversely, Sultran's commitment to the industry.

The User Agreement formed the basis of Sultran's service structure

and remains basically the same to this day. The Agreement is an

evergreen contract that automatically renews itself every three

years. Cancellation of this contract is possible by either party

and requires one year's notice prior to each renewal date, thus

illustrating the stability of this company. The current term of the

user agreement runs to December 31, 1999 and involves 24 user

customers. Sultran has been fortunate in never having had a User

Agreement cancelled.

On February 1, 1977, Sultran became fully operational. Sultran's

first billing on February 4, 1977 consisted of 8,083 tons for Shell

Canada Resources. Although the great strides of the company had not

yet been reached, it was the beginning of a union between Sultran

and its sulphur customers and shareholders, that would continually

progress and, in time, have a major influence on the sulphur

industry.

The logistics, handling and terminalling of this commodity is a

very involved and highly structured process. Rail cars are

currently scheduled into as many as 11 plants in Alberta and

British Columbia to pick up and load the sulphur. The quality of

the product is carefully monitored to insure industry standards are

met. Canadian sulphur is among the purest in the world produced at

99.9% pure. It is important to maintain this level of purity

throughout the transportation process and have it delivered to the

customer in this highly refined state. The trains are tracked and

expedited from point of origin to tidewater destination. Labour

force requirements, including independent testing companies, are

ordered to coincide with arrival times. Once at port, the sulphur

is either stored in stockpiles or loaded directly to vessels. The

commodity is tested further before being lifted onto vessels for

delivery overseas. Throughout the process of transporting the

sulphur, Sultran carefully takes into consideration the well-being

of the environment while strictly adhering to regulations and

policies that govern the industry. It now becomes obvious that the

transporting of this commodity to international markets is so much

more than a simple "train ride".

By the 1980's Sultran was solidly established and ready to forge

ahead. The success of working together with major sulphur

producers, marketers, railways and other suppliers had afforded

increased and reliable access to offshore markets and

ever-expanding volumes of business were being realized. New levels

of efficiency and advanced capabilities allowed sulphur producers

to better compete in global markets. The need to increase

efficiency and reliability and to reduce environmental impact led

Sultran to begin making major investments in rail cars and terminal

facilities. These investments provide solid returns to Users in

efficiency, reliability and lower costs over the long term. The

long range commitments made to Sultran by the producers made these

investments and improvements possible and allowed Sultran to plan

and develop for the future.

Since its beginnings in 1976 Sultran has always had strong support

at the Board level as well as from producers and marketers. The

Board of Directors have given Sultran the support required to allow

the organization to move forward. Much of the progress Sultran has

made is the direct result of the investment of capital in system

improvements. From the acquisition, renovating and building of

facilities and the establishment of related companies, to the

continuing purchasing and upgrading of equipment that allows

operations to run smoothly, Sultran and its subsidiary companies,

Pacific Coast Terminals Co. Ltd. and PDS Rail Car Services

Corporation, have not only been able to achieve significant results

in their industry, but have had positive impacts on their

surrounding environments.

|